How we work

This is how we manage our projects

Centrifugal Pump Design, upgrade and CO2 reduction

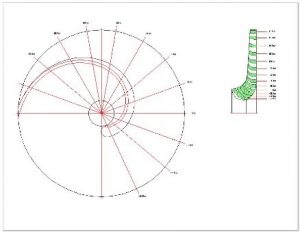

Our company is able to design or support your Design Team from drawing board to production pumps according to latest specifications. We can support you in analyzing the pump performance test at test bed or at site and consequently its interaction with the system. We will follow this by best solution for the existing pumps and installations to achieve optimum performance, efficiency improvement and environmentally friendly operation.

Our activities vary between designing new hydraulics / modifications of existing components and troubleshooting, and choosing /selecting the best pump selection or system.

Activities

– Hydraulic components design according to latest international specifications. (ISO, API etc..)

– Special applications design, such as low NPSH-impeller, inducer

– Prototype design and manufacturing.

– Bearing and shaft design acc. to all international standards like API etc..

– Nozzle loadings and stresses

– High/low temperature applications

Retrofit & Performance Enhancement

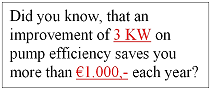

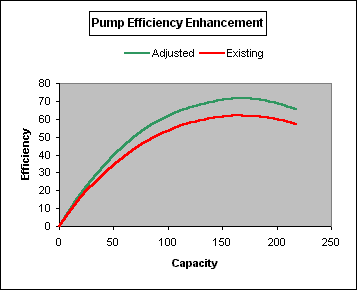

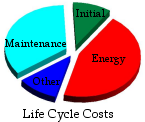

Have you ever thought that it is possible to save costs by enhancement of your machine? Not only in saving on power input, but also in spending less money in maintenance?

PFSTC is able to analyze and optimize your pump and system.

In most of the cases existing equipment can be accommodated with RETROFIT components to achieve energy consumption and CO2 reduction.

In case of designing new and better components, we are also able to supply these components at competitive Leadtime pricing (also castings).

Remember this: there is always room for improvement!

Contact PFSTC let us determine where your possible saving areas lie.

Activities

– Debottlenecking and Process Optimization

– Efficiency improvement

– NPSH improvement

– Bearing life, increasing Mean Time Between Failures

– Upgrading pump performance curve

– Cost saving modifications

– Design and manufacturing of required components.

Commercial & Technical Evaluation & Management

With years of experiences in technical and commercial field, we are able to support you in required evaluation, negotiation and consequently the cost saving aspects of the project.

We can support you in different stages of the project, from visibility, FEED to EPC phase.

Preventive Maintenance

Have you ever calculated how much money you can save by selecting good preventive maintenance?

Are you often faced with downtime of equipment at inconvenient times?

It is essential in preventive maintenance to analyze your equipment and system for optimal operation. This will lead to a trouble free and longer lifetime of the equipment and ancillaries.

Monitoring is necessary for insurance equipment, but only on essential parts, which will give you enough information on the actual momentary status.

PFSTC can help in creating a well-thought and cost-effective monitoring solution for your equipment.

Activities

– Increasing Mean Time Between Failures

– Pump monitoring

– Correct pump selections

– Correct process conditions

Training & Consultancy

The most important factor in an optimum pump/system performance is the pump selection.

Not all pumps are suitable for a specific duty, and not all duties are suitable for a specific pump.

Good selection and designing of your pump/system can prevent you from potential problems, unscheduled downtime of the equipment and save you a lot of money.

Because of more than 30 years experience within our company in this field, we are able to give you an experienced and knowledge based training and INDEPENDENT consultancy.

Activities

– Pump technology training

– Pump selections

– Interaction between pump and system

– Support on piping design and improvement of operation of rotating equipment.

– Evaluation and comparison of quotations

– Pump Monitoring

– Process data analyzes

– Vibration analyzes.

Project Management

With Years of experience, we are able to support you in managing your projects to success. With our effective communication skills, we will support you from Kick-off to stakeholders’ meetings. Our knowhow in product and production management will support you in time and risk management.

Technical and commercial knowledge will be always a great resource in different phases of projects. We support you in conflict management, trouble shooting and eventual negotiations.

Reliabelity Engineering & Trouble Shooting

Pump users often face problems with rotating equipment. Efficiency drop, vibrations, cavitation, system changes, misalignment, high thrust, bearing failures are some of these common problems. To solve these complex issues, specialism and experience is required. Because of our 30 years of experience in production as well as operating fields, PFSTC is your partner in solving and eliminating of these problems. You will soon be able to return to your flawless operation and your core business.

Have you ever calculated how much money you can save by selecting good preventive maintenance? Are you often faced with downtime of equipment at inconvenient times?

To manage and improve downtime interval, we review pump and system parameters to boost your equipment and system for optimal operation. This will lead to a trouble free and longer lifetime of the equipment and ancillaries.

Monitoring is necessary for insurance equipment, but only on essential parts, which will give you enough information on the actual momentary status.

PFSTC can help in creating a well-thought and cost-effective monitoring solution for your equipment.

Activities

– Pump failures

– Efficiency drop

– Seal failures

– Cavitation

– Wear and tear

– Vibrations

– Pressure loss

– System failure/problem

– Increasing Mean Time Between Failures

– Pump monitoring

– Correct pump selections

– Correct process conditions

Contact us

Do you have any questions? Or do you want to get in touch? Feel free to contact us. We’ll reply as soon as possible.